The Impact of Cleaning Agents on Chemical Contamination in Food Processing

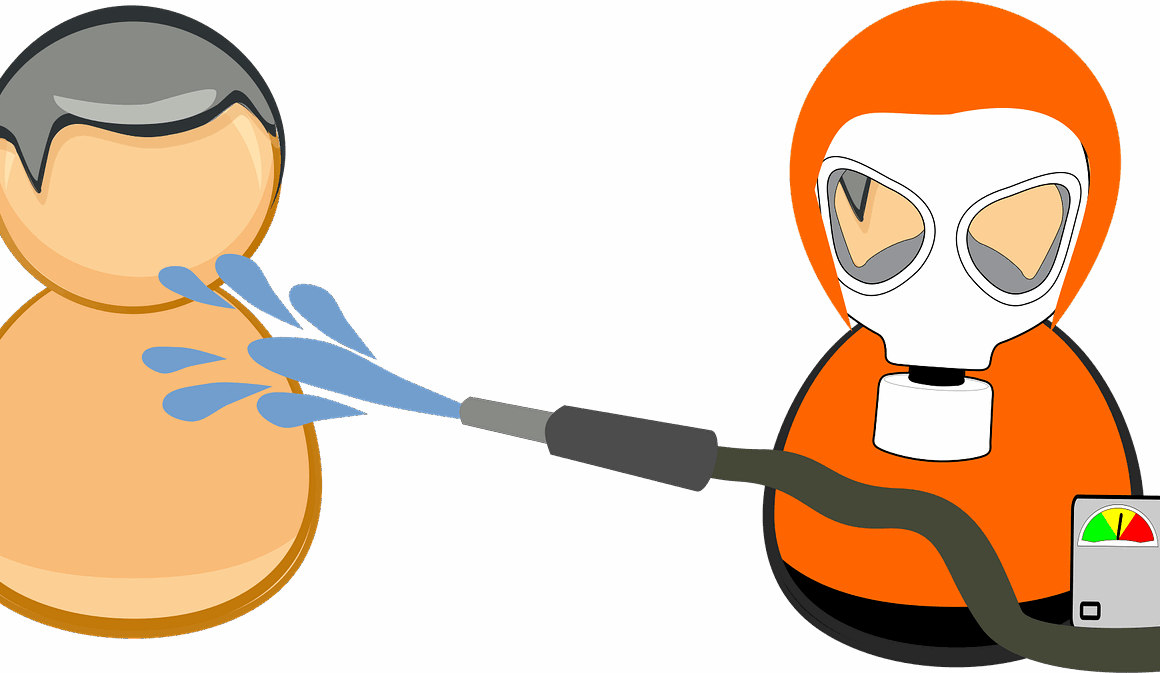

The safety of food processing is critically important to ensure consumer health. Various factors contribute to contamination, including the use of cleaning agents that may contain harmful chemical residues. For manufacturers, understanding the implications of these agents is essential. A thorough analysis of cleaning agents could significantly reduce risks. During food processing, cleaning agents are utilized to maintain hygiene standards. Proper use is vital, as improper application could lead to severe contamination. It is essential to select cleaning agents that are effective against pathogens yet safe for food contact surfaces. Additionally, regulatory agencies have established guidelines to maintain safety standards. However, it is crucial that food processors regularly evaluate the cleaning agents in use. Some agents may leave toxic residues if not adequately rinsed. This highlights the need for rigorous training among staff overseeing cleaning procedures. Continuous education can foster awareness regarding food safety associated with cleaning agents. Ultimately, the objective should be to find a balance, ensuring cleanliness without compromising food safety. Food processors must prioritize the careful selection of cleaning agents to minimize contamination risks in the food supply chain.

Chemical contamination can arise from various sources in food processing. Cleaning agents represent a significant concern, especially those containing harsh chemicals. These are often residual contaminants from cleaning processes. Possible chemical pollutants include phosphates, bleach, and glycerin, among others. It is crucial for manufacturers to choose cleaning agents that do not interact negatively with food products. For instance, bleach is effective in many cleaning applications but can leave traces that impact food safety. Residues from cleaning agents can lead to health risks for consumers. Ingesting contaminated food can cause illness, impacting public health. This risk emphasizes the need for washing and rinsing protocols to eliminate residues effectively. Furthermore, companies must conduct regular audits to assess the effectiveness of cleaning procedures. Innovations in green cleaning solutions also provide alternatives with reduced health risks. By opting for products with biodegradable ingredients, manufacturers can enhance safety without sacrificing cleaning efficiency. Ultimately, reducing chemical contamination in food processing requires diligence and commitment from all stakeholders. The adoption of safe cleaning practices is essential for the food industry to protect consumer health and maintain trust in food safety standards.

Best Practices for Cleaning in Food Processing

Implementing best practices in cleaning processes is vital for food safety. Manufacturers must adhere to stringent guidelines to mitigate contamination risks from cleaning agents. First, a robust cleaning schedule must be established. This schedule should prioritize high-risk areas and equipment frequently exposed to food products. Also, the selection of appropriate cleaning agents is critical. Non-toxic and food-safe cleaning solutions should be prioritized. Another essential practice is to ensure thorough rinsing procedures after using cleaning agents. Proper rinsing removes residues, significantly reducing potential contamination. Training staff is an integral part of maintaining cleaning effectiveness. Employees must understand the importance of following safety protocols diligently. Regular training sessions can help staff recognize the risks associated with improper cleaning methods. Monitoring and documenting all cleaning activities is essential for accountability and compliance. Conducting routine inspections can reveal areas needing improvement. Additionally, companies should keep abreast of regulatory changes. Food safety regulations evolve frequently, and compliance is mandatory. The integration of these best practices will promote a safer food processing environment. Manufacturers who prioritize these cleaning protocols will enhance food safety and ultimately protect public health.

The adoption of modern technologies in food processing can also enhance safety measures. For instance, advancements in chemical testing help ensure cleaning agents are free from harmful contaminants. Technologies such as rapid microbiological testing tools enable food processors to evaluate the cleanliness of surfaces after cleaning. This can significantly reduce the risk of chemical contamination. Moreover, implementing automated cleaning systems can ensure uniform application of cleaning agents. Automated systems can adjust concentrations and application methods to minimize residual chemicals. Additionally, utilizing eco-friendly cleaning agents can effectively reduce the environmental impact while ensuring safety. Many green solutions are designed to be safe for food contact and have minimal toxic residues. Companies that embrace innovation often find they improve both efficiency and safety. The commitment to ongoing research and development can lead to better cleaning solutions tailored to the food industry’s needs. The ultimate goal should be maintaining high hygiene standards while protecting consumers. Continuous improvement in cleaning technologies presents an opportunity for the food industry to address the challenges of chemical contamination effectively. As food safety issues rise globally, proactive solutions from manufacturers are more critical than ever.

Regulatory Guidelines and Compliance

Compliance with regulatory guidelines is non-negotiable in the food processing industry. Various agencies, such as the FDA and EFSA, establish regulations that dictate acceptable levels of residues from cleaning agents. These guidelines are paramount for ensuring consumer safety and maintaining industry standards. Food processors must stay informed about legal requirements to avoid potential legal issues. Regular training sessions on these guidelines are necessary for all employees. Understanding compliance ensures that everyone is aligned with food safety mandates. Companies must develop and maintain comprehensive documentation that tracks the use of cleaning agents. This includes records of cleaning schedules and the agents used. Audits and inspections are beneficial in assessing compliance with regulations. Engaging third-party auditors can provide an objective view on adherence to cleaning protocols. Furthermore, any changes in cleaning agents or procedures must be documented meticulously. This transparency fosters confidence among stakeholders that safety is a priority. When companies cultivate a culture of compliance, they enhance their brand reputation. Maintaining rigorous adherence to regulatory standards protects consumer health and strengthens public trust in the food industry.

Consumer awareness regarding food safety is essential and growing. As people become more educated about food processing, they demand better practices from manufacturers. This increased scrutiny shapes the industry’s approach to chemical contamination and cleaning agents. Public concern about health risks encourages food processors to adopt safer cleaning methods. Consumers are interested in understanding what they consume, including how their food is cleaned and processed. Brands that prioritize transparency and disclose cleaning practices often build customer loyalty. Engaging with customers through educational campaigns is an effective way to foster trust. Providing information on how cleaning agents are selected and used enhances consumer confidence. Additionally, collaborating with consumer advocacy groups can facilitate better communication about food safety issues. This two-way engagement can lead to improved practices across the industry. As consumers voice their concerns, manufacturers must adapt to meet expectations. The repercussions of negligence can be severe, impacting brand reputation and customer trust. In this environment, the proactive approach to cleaning processes has never been more critical. Addressing consumer concerns about chemical contamination must be at the forefront of food processing strategies for the future.

Future Trends in Food Safety

Looking towards the future, trends in food safety will focus on innovation and sustainability. The food processing industry is evolving with a growing emphasis on environmentally friendly practices. As regulations become more stringent, companies will need to invest in safer alternatives to conventional cleaning agents. Innovations in nanotechnology and bio-based cleaning agents are emerging. These new cleaning solutions promise effective sanitization with reduced toxicity. Moreover, the trend towards cleaner labels in food products is gaining momentum. Consumers increasingly prefer products made without harmful chemicals. This shift requires manufacturers to rethink their cleaning processes and formulations. Organizations that embrace sustainable practices are likely to succeed in attracting environmentally conscious consumers. Furthermore, the integration of data analytics in monitoring cleaning processes will allow for real-time adjustments. This can help ensure compliance with food safety standards while minimizing chemical residues. The industry must remain adaptable to changing consumer preferences and regulatory landscapes. Future trends will undoubtedly shape strategies for chemical contamination control in food processing significantly. By prioritizing innovation, safety, and sustainability, food processors will secure a healthier future for consumers.

In conclusion, the impact of cleaning agents on chemical contamination in food processing is profound and multifaceted. Manufacturers must actively engage in ensuring the safety of their products throughout the cleaning process. This involves understanding the chemicals in cleaning agents and their implications. Utilizing safe cleaning practices is essential in minimizing risks associated with contaminants. Additionally, adhering to local and international regulations fosters consumer confidence. Education plays a pivotal role in this process, ensuring all employees understand food safety protocols. The collaboration between industry stakeholders, including suppliers and regulatory bodies, will also drive positive change. Companies that prioritize transparency and communication will build stronger relationships with consumers. As we navigate the complexities of food safety, continuous improvement should be a core objective for the food industry. Adaptation to new technologies, regulations, and consumer expectations is necessary for future success. Ultimately, protecting public health is paramount, and food processors must remain vigilant in their efforts. The quest for safer food will continue to evolve, but the commitment to reducing chemical contamination will define the future of food processing.