Sanitation SOPs: Ensuring Safe Food Handling

Food safety is of paramount importance for public health, and Sanitation Standard Operating Procedures (SSOPs) play a vital role in maintaining this safety. SSOPs outline the necessary practices and procedures to ensure a safe environment for food preparation and handling. These procedures address areas like equipment cleaning, pest control, staff hygiene, and food storage. Awareness of SSOPs helps in minimizing foodborne illnesses, which can cause severe health issues and economic loss. Therefore, creating and adhering to SSOPs is an obligation for all food handlers. The development of effective sanitation procedures requires thorough training for employees on best practices in sanitation. This commitment starts with management supporting a culture of hygiene. Training sessions can include hands-on demonstrations, refresher courses, and materials for employees to study. Additionally, regular audits and evaluations can determine the procedures’ effectiveness and staff compliance. Monitoring progress supports continuous improvement in food safety standards. By fostering a comprehensive sanitation framework, food establishments can protect their customers from potential health hazards, ensuring that they provide safe and nutritious food while maintaining their reputation and enhancing customer trust.

Developing effective Sanitation Standard Operating Procedures involves several essential steps. First, identifying specific sanitation tasks is vital to ensure thorough coverage. Each identified task should be broken down into clear, manageable actions, detailing the correct methods for cleaning and sanitizing various surfaces and equipment. Responsibilities must be assigned to individuals, ensuring accountability for the implementation of each task. Furthermore, it is crucial to select appropriate cleaning and sanitizing agents that meet regulatory standards. The selection process should consider the efficacy, safety, and cost-effectiveness of the products being used. All employees should understand the importance of proper usage and any associated risks. Additionally, documenting protocols with detailed instructions encourages compliance from staff members. Regular training on the SSOPs should be conducted to reinforce knowledge and adaptability amongst employees. A feedback mechanism where staff can report challenges with the procedures can enhance problem-solving. Continuous assessment is critical to maintain high standards of hygiene as conditions may change, necessitating adjustments to procedures. Periodic reviews of the sanitation policies should be scheduled to reflect updates in regulations or advances in sanitation technology.

Employee Training and Compliance

Training employees on Sanitation Standard Operating Procedures is critical to ensuring compliance and promoting a culture of safety. Training programs should encompass information on the importance of sanitation in food safety, including how certain practices can significantly reduce the risk of contamination. Engaging training methods such as interactive workshops or on-the-job demonstrations are beneficial for employee understanding. Utilizing visual aids can also reinforce learning, making the process more engaging. Furthermore, employees should be trained on recognizing signs of potential contamination and the steps involved in corrective actions. Establishing a clear understanding allows for swift responses to unsanitary conditions. Employers must verify employee comprehension through assessments and feedback sessions. Regular re-training intervals will help reinforce the importance of following sanitation protocols, regardless of employee experience levels. Certificate programs can also incentivize individuals to take sanitation training seriously. Maintaining documentation of employee training sessions is also best practice for accountability, showcasing compliance during audits. Additionally, fostering open communication where employees feel comfortable discussing sanitation concerns creates a proactive environment for food safety.

Monitoring and verifying compliance with Sanitation Standard Operating Procedures is essential for maintaining food safety. Establishing a monitoring system involves creating checklists or logs to document sanitation practices, ensuring tasks are completed as scheduled. Daily inspections of food preparation and storage areas allow management to analyze and evaluate sanitation effectiveness thoroughly. Regular monitoring ensures adherence to sanitation protocols and unveils any areas requiring improvement. Conducting surprise audits can also keep staff vigilant about their adherence to protocols. Furthermore, corrective actions should be promptly implemented when infractions occur to minimize risks. Providing feedback on audit results to management and staff encourages an atmosphere of transparency and accountability. Continuous training in response to monitoring findings ensures that employees understand the evolving nature of food safety. Monitoring should not solely be numeric; qualitative assessments of employee performance in sanitation practices must also be included. Recognizing employees who adhere to sanitation best practices fosters a positive culture that prioritizes food safety. Investing in sanitation compliance management enhances overall efficiency, minimizes health risks, and can lead to improved customer satisfaction.

Cleaning Procedures

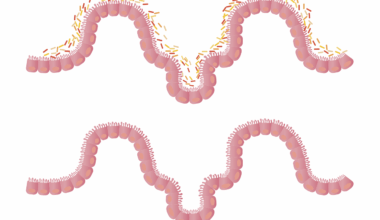

Effective cleaning procedures are core components of Sanitation Standard Operating Procedures in any food handling environment. The first priority is to determine which areas and equipment require regular cleaning and sanitizing. High-touch areas, such as food contact surfaces, utensils, and equipment, need frequent attention to prevent contamination. Daily cleaning schedules should be developed and followed, detailing specific tasks and responsibilities. Furthermore, proper cleaning methods and agents suitable for use in a food establishment must be unequivocally outlined in the SOPs. For instance, the usage and dilution ratios of cleaning chemicals should be specified for efficacy while ensuring safety. Additionally, priority should be given to cleaning during non-peak hours to minimize disruptions to customer service. It’s vital that staff members understand the difference between cleaning, sanitizing, and disinfecting, as each process serves a distinct purpose. Reinforcing this knowledge through routine training helps in the application of procedures. Lastly, a register should be maintained to record all cleaning activities, ensuring transparency and accountability in maintaining hygiene standards.

Pest control is an essential part of effective Sanitation Standard Operating Procedures within food establishments. Having a robust pest management plan helps in reducing the risks of infestation, which can lead to significant public health hazards. Regular inspections should be performed to identify any potential entry points, nesting, or breeding areas for pests. Collaborating with professional pest control services enhances the overall strategy. Additionally, staff training on recognizing signs of pests and preventive best practices is critical for immediate action before a situation escalates. Establishing proper waste disposal procedures ensures that trash does not attract pests, minimizing their presence. All food items should be stored in securely sealed containers, reducing the chances of pest contamination. In addition, maintaining the cleanliness of outdoor areas, including landscaping and docking stations, helps deter rodents and insects. A consistent monitoring system is necessary for evaluating the effectiveness of pest control efforts, which should include regular documentation of sightings and management actions taken. Reporting any pest activity immediately to management ensures that action can be taken swiftly, safeguarding the safety of food products.

Documentation and Record Keeping

Proper documentation and record-keeping are fundamental aspects of Sanitation Standard Operating Procedures, providing a clear trail of accountability and compliance. Records should be maintained for all sanitation tasks, including cleaning schedules, training sessions, and audits. Utilizing digital management systems can streamline documentation processes, ensuring accessible information for all team members. Each record must include the date, time, individuals involved, and specifics of the sanitation activity performed. Furthermore, retaining copies of chemical safety data sheets is essential for transparency regarding cleaning agents used in the establishment. A well-organized filing system aids in producing records during health inspections, showcasing adherence to sanitation standards. Regularly reviewing these documents aids in identifying trends or recurring issues that may need further attention. Employee training logs should also be updated frequently, illustrating a commitment to sanitation compliance. Documenting employee performance, especially in relation to adherence to sanitation protocols, can foster an environment of accountability. Finally, periodic audits of the documentation itself ensure that the system is functioning effectively, allowing for continuous improvements in food safety practices.

In conclusion, the implementation of robust Sanitation Standard Operating Procedures is vital for ensuring safe food handling practices. Compliance is essential for safeguarding public health while fostering trust with consumers. It requires a collective effort from all employees to adhere to the established protocols. Continuous training, compliance monitoring, and improvement measures are essential to maintain high standards in sanitation and cater to evolving health regulations. The collaboration between management and staff creates a strong hygiene culture within food establishments. Therefore, investing in SSOPs not only meets legal requirements but also contributes to substantial economic benefits from reduced foodborne illnesses. It demonstrates a commitment to quality and safety, positioning the business favorably in the market. The effort to remain vigilant in food safety and sanitation will pay dividends in customer loyalty and brand reputation. Food safety is everyone’s responsibility, and maintaining sanitary conditions will lead to better public health outcomes. Regularly revisiting and updating the sanitation procedures can help establishments stay ahead in compliance and innovation. In a world increasingly focused on health, operating with stringent sanitation protocols is vital for success.