pH and Temperature: Key Parameters in Fermentation Science

Fermentation science relies heavily on specific conditions, particularly pH and temperature, for optimal microbial activity. These parameters are crucial in determining the quality and safety of fermented foods. Manipulating pH can affect enzymes, yeast, and bacteria involved in the fermentation process. For example, lactic acid bacteria thrive in lower pH environments, leading to more pronounced sour flavors in products. Similarly, temperature influences the rate of fermentation and the microbial community present. Higher temperatures may speed up the fermentation, but excessive heat can kill beneficial microorganisms. Thus, understanding the balance between temperature and pH is essential for consistent fermentation outcomes.

The process of fermentation is not uniform; different foods require tailored environments to achieve desired characteristics. For instance, while yogurt fermentation occurs ideally at around 110°F (43°C) and a pH of about 4.5, beer fermentation often takes place at temperatures ranging from 65°F to 75°F (18°C to 24°C). The diversity in temperature and pH preferences is largely due to the specific strains of yeast and bacteria utilized in each type of food processing. Those managing fermentation processes must consider these variables carefully to produce aesthetically pleasing and flavorful products.

The relationship between pH and fermentation is multifaceted. A decrease in pH during fermentation is often associated with the production of organic acids, contributing to flavor development and preservation of the product. Acidic environments inhibit spoilage organisms, thus enhancing food safety. Additionally, the fermentation medium’s buffering capacity can affect pH changes, necessitating measurement and adjustment. For optimal fermentation, a careful monitor of pH levels is essential, as deviations can lead to undesirable outcomes, including off-flavors or spoilage. To ensure the desired product quality, fermentation practitioners must regularly assess and adjust pH as needed.

The Impact of Temperature on Fermentation

Temperature impacts the metabolism of microorganisms and their growth rates significantly. Optimal temperatures allow for rapid growth and activity while temperatures that are too low can slow down the fermentation process. Moreover, excessive heat can destructively affect flavor compounds, nutrient availability, and even microbial viability. Traditional fermentations often rely on ambient temperatures, but controlled environments such as fermentation chambers can greatly benefit consistency. It’s recommended to document temperature changes throughout the fermentation process to create reproducibility for future batches.

Microbial activity during fermentation generates heat; thus, maintaining a stable temperature can be challenging. Excessive heat build-up can occur in large batches, which may result in hot spots leading to inconsistent fermentation. This is crucial in commercial production, where uniform quality is expected. A balanced approach often involves cooling systems or regular mixing to ensure an even temperature throughout the mixture. Moreover, understanding the thermal characteristics of the microbial culture, such as heat tolerance levels, will inform the overall fermentation process design for better productivity.

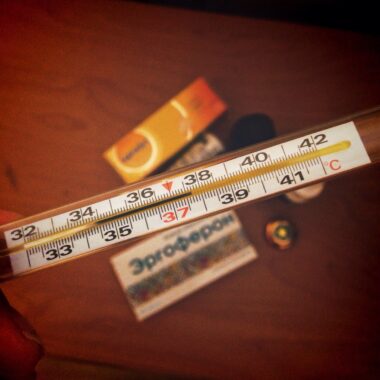

As fermentation continues, monitoring pH and temperature becomes vital for both safety and quality. For example, if pH levels rise beyond optimal limits, interventions must be made to restore balance—like adding acidifying agents. Similarly, if temperatures exceed safe ranges, cooling strategies should be employed promptly to protect microbial life and preserve flavor integrity. Therefore, fermentation practitioners are advised to implement real-time monitoring systems, which can significantly help manage these key parameters effectively and ensure that product quality is consistently achieved.

Conclusion on pH and Temperature

The study of pH and temperature within fermentation science is essential for producing high-quality fermented foods. By controlling these variables, producers can influence sensory attributes, shelf-life, and safety aspects of their products. Understanding the unique requirements for different fermentation systems enables food scientists and producers to optimize conditions for specific applications. Enhancing knowledge about pH and temperature relationships can foster innovative approaches in fermentation technology, leading to new products and improved production methodologies.

In light of the growing fermented food market, the significance of mastering fermentation pH and temperature cannot be overstated. These factors are intertwined in complex ways that affect the final product. Continuous research in this field can uncover more insights into how these conditions impact fermentation processes. As fermentation practices evolve, embracing modern technologies for monitoring and control will usher in exciting advancements in the art and science of food fermentation, ensuring that quality remains paramount.